How Automation Solutions Enhance Profit Margins and Operational Efficiency

How Automation Solutions Enhance Profit Margins and Operational Efficiency

Software-based document automation solutions, like ImageSite, have been helping organizations across the world improve processes by reducing legwork and providing them with a place to store, protect, and organize their digital files. More and more, engineers are turning to EDMS (electronic document management systems) solutions to manage their CAD files and their associated workflows that encompass their everyday tasks. Understanding how software automation impacts critical processes is paramount to improving the bottom line of process-driven organizations. In recent years, growth in engineering-related industries has necessitated faster and more efficient operations to achieve and sustain a competitive advantage. Automation solutions impact the bottom line by improving processes, productivity, and collaboration and reducing rework.

In this blog, we cover the following:

Automation solutions improve the bottom line

Before seeking improvements, companies need to analyze their organizational objectives and determine which key performance indicators (KPI) have the highest impact on their goals. Largely, these goals include:

- Value Creation

- Customer Experience

- Profitability

- Growth.

While some organizations may have other goals in mind (e.g., non-profit organizations), most engineering-oriented companies are growth-centric, and therefore must do their best to find alternative ways to improve the KPI scorecards of their engineers. A KPI scorecard is a term used to describe a statistical record that measures the progress or achievement of specific goals.

Similarly, engineers often have a comprehensive scorecard consisting of data from their individual efforts and collaborative performance across teams, departments, and organizations. While KPIs vary between firms, some of the most common indicators include:

- Cost Per Employee (CPE)

- Cost of Production (COP)

- Time to Market (TTM)

- Defects Per Unit (DPU).

Many of the key performance indicators used are interrelated, and can simultaneously be improved by automating one or many individual workflows.

Studies show the cost of rework in civil engineering projects is typically 5-15% of a project’s total cost, and can in some cases reach even 35%.

Source: AutoDesk

Cost Per Employee (CPE) and Cost of Production (COP)

Cost of production (COP) refers to the total cost incurred by an entity to produce a product or service per the number of employees required to accomplish production. Several categories factor into a company’s cost of production, including the cost of raw materials, quantity of products, and labor costs.

The quickest and easiest way to reduce the cost of production is by reducing labor costs. Labor costs are a weakness for many firms, as they can account for as much as 70 percent of a company’s COP. Labor doesn’t just concern the workers who are assembling the products but also consists of the engineers who research and design the products.

According to the Bureau of Labor Statistics (BLS), the average U.S. engineer earns a median annual wage of $91,010 (significantly higher than the average median income for the United States). Consequently, it is in a firm’s best interest to make the most of their engineers’ time at work.

Engineers often get bogged down with menial tasks like document management, including searching for and handling documents, document versioning, file transmittals, and document-centric communications. Automating these processes can significantly diminish the time required by engineers throughout the development phase of a project, reducing the amount of time it takes to produce a product.

Time to Market (TTM)

In commerce, time to market (TTM) is the time it takes from the conception of a product or project to when it is available to consumers. Reducing time to market ensures companies can achieve their return on investment (ROI) quickly, and therefore, increase profitability. Automating document-centric processes shortens the product and project life cycles, ensuring organizations meet demand and capitalize on opportunities.

Organizations can also automate critical engineering workflows since design reviews and approvals, and engineering change orders (ECO) often use complex workflows. Throughout these workflows, there are various actions employing documents which can be automated to save time and improve accuracy, helping organizations bring their product and project to market faster. In ImageSite, these actions include:

- Moving a File or Document

- Copying a File or Document

- Publishing a File or Document

- Archiving a File or Document

- Deleting a File or Document

- Launching a Transmittal

- Changing User Permissions

- Creating a Custom Field

Engineering Workflow

Automatically manage and distribute files and documents for review, approval, and processing. Adjust user permissions at each step, ensuring your company’s files are managed securely.

Defects Per Unit (DPU)

Defects per unit (DPU) is calculated by dividing the number of defects by the number of products produced. For example, if there are 10 defects in 100 units, then the DPU will be 0.1. While defects may be inevitable in many cases, engineers can significantly reduce this number through careful planning and execution. (Though in six-sigma manufacturing the defect goal is no higher than 3.4 per one million.)

It may come as a surprise that versioning plays an important role in ensuring minimal defects. There have been many cases where engineers have accidentally passed on the incorrect and unapproved version of a document to manufacturers or constructors, unknowingly instructing them to manufacture or build defective products and facilities. Ensuring engineers are working with the correct version not only reduces defects but can also reduce rework, limiting the total product/project cost per employee. Automating version control is the best way to ensure correct versions are distributed. In summary, automation solutions impact the bottom line by improving processes, productivity, collaboration and by reducing rework.

KPIs and Organizational Goals

Organizations can achieve higher profitability and growth by focusing on improving these key performance indicators. Limiting the number of actions taken by workers helps organizations streamline engineering projects and elevate productivity. This, in turn, enhances their customer experience by enabling them to bring products to market faster and create value by creating quality products and projects with minimal defects.

Additional EDMS Features

Our EDMS solutions

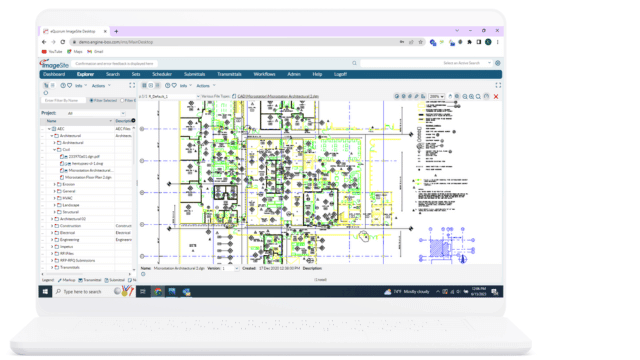

ImageSite and EngineBox are eQuorum’s robust workflow and document management solutions, created to help workers manage their essential workflows while maintaining complete control over their engineering files and documents. Not only do they provide a secure collaboration site for workers, but they also help organizations manage document distribution with third parties like vendors, contractors, and customers. Both systems are offered at a competitive price, enabling organizations to get a quick return on their investment by providing the features and functionality needed to help organizations improve efficiency, productivity, and collaboration. Companies can choose from concurrent user subscriptions or named user subscriptions, ensuring organizations have subscription options that make sense for their business.

ImageSite®

Our single source engineering workflow and document management system. Built in HTML5 so there is no software to deploy to client computers or mobile apps to download. Offered as an On-premise or Private Cloud system.

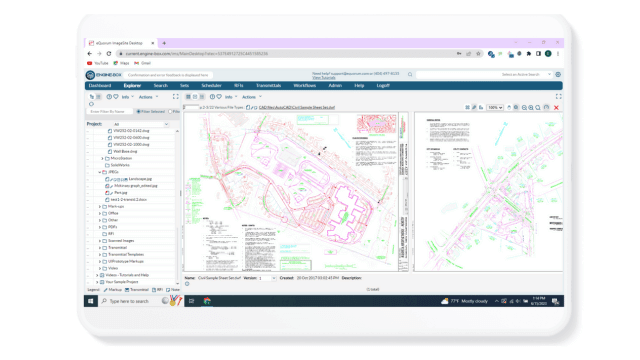

EngineBox™

EngineBox is a cloud based workflow and document management version of ImageSite that resides outside the corporate network.

Our EDMS solutions

ImageSite and EngineBox are eQuorum’s robust workflow and document management solutions, created to help workers manage their essential workflows while maintaining complete control over their engineering files and documents. Not only do they provide a secure collaboration site for workers, but they also help organizations manage document distribution with third parties like vendors, contractors, and customers. Both systems are offered at a competitive price, enabling organizations to get a quick return on their investment by providing the features and functionality needed to help organizations improve efficiency, productivity, and collaboration. Companies can choose from concurrent user subscriptions or named user subscriptions, ensuring organizations have subscription options that make sense for their business.

EngineBox™

EngineBox is a cloud based workflow and document management version of ImageSite that resides outside the corporate network.

The eQuorum Customer Promise

In 2005, eQuorum developed the first all browser-based EDMS. The system, although for on-premise use, was still created to remove client software and JAVA from user computers and allow users to have a single viewer based on the simple navigation functionality of browsers. Today, eQuorum provides that same application in a private Cloud or a SaaS Cloud option. We can do this because we are, and have always been, browser-based, understanding the enhanced speed, security, and usability of this technology.

With the abundance of document management systems on the market today, there’s no doubt that choosing the right Cloud document management software can be a difficult decision. eQuorum is here to provide a comprehensive, powerful, and most importantly – affordable Cloud document management solution. We believe in providing real value to our customers by eliminating unnecessary costs, providing industry-leading functionality, and equipping your team with the right tools using cutting edge technology to bring your products to market faster.

eQuorum®

We specialize in engineering workflow and document management. Our comprehensive, yet easy-to-use software provides the solution to manage data from design to manufacturing and production, to sales, support and administration.